Enhancing Efficiency with FRP Molded Grating Machines

The world of industrial manufacturing alone has a plethora of advancements in machinery, for example, FRP molded grating machines. These machines play a vital role in improving operational efficiencies by providing a consolidated production line solution that can serve wide-ranging industrial requirements. These Machines are essential components that are used to boost the operational potential and produce the material with advanced quality and machines suited for varied industrial requirements.

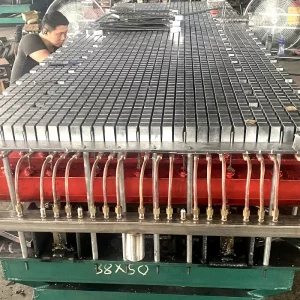

Streamlined Production Processes

Machines are designed for maximally effective production workflows of molded grating from FRP. These machines automate most of the manufacturing processes to maintain consistent quality and precision in all grating. The automatic lift mechanism, plus the feature of rapid heating achieves effective and rapid capabilities of operability and hard mold demolding thus speeding up the production cycle time.

Durability and Longevity of FRP Gratings

To put it simply, the durability of FRP gratings is an indication of how efficient these machines are. FRP gratings are made of top-notch materials, and the new procedures have further enhanced their resistance against corrosion, wear, and even impact. The long life means lower maintenance costs and longer service life, making them an ideal choice for industries that require a strong solution. As these gratings are made out of materials with anti-corrosive properties, it makes them structurally sound under harsh environmental conditions.

Customization Capabilities

One of the notable advantages of FRP molded grating machines is their ability to offer customization. Aoliande, as a leading manufacturer, understands the importance of catering to the specific needs of customers in industries like automotive, construction, and marine. By deploying Aoliande’s customized grating machines, manufacturers can meet the diverse requirements of their clients, whether it’s regarding size, shape, or arrangement. This flexibility not only expands market segments but also ensures that customers receive the perfect solution for their specific applications.

Cost-Benefit Analysis of Implementing FRP Molded Grating Machines

Initial Investment Considerations

The initial purchase cost for FRP molded grating machines consists of procurement, installation, and training costs. However, manufacturers will have to weigh these costs — against possible benefits like higher production and better quality. These machines are often heady with technological sophistication that may require some upfront investment but are virtually assured of dividend returns through increased efficiency and output.

Operational Cost Savings

FRP molded grating machines pay for themselves in savings once they are up and running. As they operate automatically, it minimizes and considerably reduces the embedded labor costs attributed to manual interventions throughout a production process. Their efficient design also reduces utility costs related to the long-term operation of the machine. Decreased material waste from precise manufacturing processes leads to a greater efficiency in cost, yet even less wastage of resources.

Return on Investment Metrics

The return on investment (ROI) on FRP molded grating machines evaluates the initial investment with all the tangible and intangible benefits received over time. Concrete gains include increased sales from larger production volumes and lower operational costs. Abstract benefits include higher quality products and better reputation in the market both of which contribute to better customer loyalty. This allows companies to interrogate these metrics holistically and determine whether their investment decisions around these technologies are financially smart.

In summary, further, FRP molded grating machines in industrial operations endow various benefits from operational efficiency to considerable savings. Enterprises can produce high levels of return on investment and win in their market by putting their better functionality to use for faster production lines and customizable flexibility. Businesses can benefit from a huge ROI and compete with key differentiators due to their enhanced flexibility in turnkey production processes and customization.

Innovations in FRP Technology and Market Trends

Recent developments in innovative Fiber Reinforced Plastic (FRP) technology innovations have emerged from a desire to create new materials that are more durable, efficient, and versatile. Such improvements have not only improved the quality of FRP materials but also widened its application in many industries. These developments have further improved the characteristics of FRP items and increased their use in different fields.

Advances in FRP Manufacturing Techniques

Changes in methods of manufacturing concerned with FRP recently have altered the scene of production, Filament winding and pultrusion, to name a few, have been optimized through digitization. For example, with the use of an advanced control system in the filament winding machine, the winding patterns can be controlled very accurately to produce higher structural integrity and better performance of the final products. Moreover, hydraulic systems in pultrusion processes maintain constant pulling force and temperature, improving the quality of the final product. It gives rise to technologies that allow manufacturers to produce complex shapes with high accuracy and in different sizes according to industrial requirements.

Market Demand for FRP Products

FRP products have unique advantages over traditional materials such as steel and aluminum, which keeps the demand growth trend very broad. Due to their light weight, strength, and resistance to corrosion, industries such as automotive, construction, marine, and aerospace are adopting FRP solutions. In the automotive sector, FRP components are used to cut car weight and increase fuel economy. Within construction, FRP is designed to reinforce construction needing energy to wear and tear in part environment. Coupled with the rising demand for sustainable, energy-efficient, and long-lasting materials, this makes FRP a material for the future.

Aoliande’s Role in the FRP Industry Landscape

Through innovative solutions and dynamic market evaluation, Aoliande has successfully carved out its place in the plan/report FRP and developed its approach as a key player in this field. Aoliande has become an important name in the FRP sector due to its expertise in the development of new solutions based on the requirements of the changing market.

Aoliande’s Expertise in FRP Solutions

With a lot of past experience with FRP technology & its application, Aoliande has an understanding of FRP very well. The company provides in-house design, manufacturing, and installation solutions. Aoliande focuses on quality assurance and continuous innovation, which guarantees the quality of its products reaches a higher standard and excels in performance. Its focus on research and development allows the firm to anticipate market trends and offer novel solutions to difficult problems faced by its clients.

Exploring Aoliande’s Other Product Lines

Apart from a great molded grating machine, Aoliande also manufactures other products that cement the company’s position as a top player in the FRP space. Aoliande is not only a directly molded grating professional machine manufacturer, but also an FRP empery vibration molding business unit, and also provides a variety of different items.

FRP Filament Winding Machine

The filament winding machines are specialized in manufacturing high strength Monofilament Pipe with maximal strength-to-weight ratio, produced by Aoliande. These machines use things like computer-controlled winding systems to guarantee the proper placement of fibers and that the resin is uniformly placed. The final products have superior mechanical properties and are suitable for high-demanding applications such as pressure vessels and pipelines. In addition, the ease of operation with which Aoliande’s filament winding solutions operate has favored many manufacturers to purchase this production equipment.

In the FRP field, Aoliande keeps pace with the times, constantly expands the scope of production, and continuously improves the production process. This commitment to provide value-added solutions not only allows its customers to achieve maximum return on investment but also engages in the advancement of modern-day industrial applications using composite materials.

To contact Aoliande, you can reach us via WhatsApp at +86-13363884492 or email them at belen@aldfrp.com for any further inquiries.