Overview of FRP Grating Machines

Definition and Purpose of FRP Grating Machines

FRP Grating Machines are tools used in industries to handle materials by cutting or shredding them into smaller pieces for processing purposes. They are essential in manufacturing processes where precision and consistency are important for efficient material handling and preparation of raw materials, for subsequent processing steps.

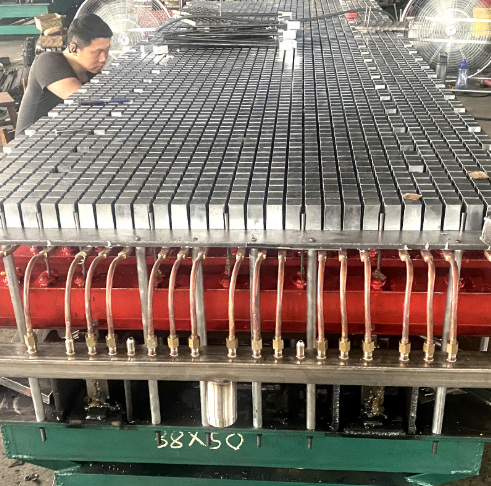

Key Components of a FRP Grating Machine

FRP Grating Machines usually have a key parts; a feeding mechanism for smooth material intake grating or cutting blades for shredding a motor for power and a discharge system to gather the processed material. Some advanced versions even come with automated controls, for precision and efficiency.

Types of FRP Grating Machines Used in Industries

Different industries use kinds of FRP Grating Machines depending on their specific needs. They often use FRP Grating Machines with rotating drums to process materials and stationary blade FRP Grating Machines for precise tasks. Industrial grade shredders are also popular, for handling amounts of material efficiently. Each type of machine is designed to meet operational requirements effectively.

Importance of FRP Grating Machines in the Chemical Industry

Enhancing Efficiency in Chemical Processing

Machines that grate materials play a role in chemical processing by making sure that raw ingredients are uniformly sized and ready, for reactions or mixing processes to take place smoothly and efficiently. Maintaining material sizes helps speed up reactions and minimize waste generation during production cycles.

Role in Material Size Reduction and Preparation

Reducing the size of materials is crucial in chemical production processes; FRP Grating Machines play a role in refining catalysts and powders to specific sizes, for enhanced blending and more effective reaction results.

Ensuring Consistency and Quality in Chemical Products

In the realm of chemical manufacturing excellence lies in the realm of maintaining product quality through a consistent lens – an element that FRP Grating Machines play a pivotal role in by ensuring particle sizes remain uniform throughout the production process.

Applications of FRP Grating Machines in Various Chemical Processes

Usage in Powder Production

During the process of making powder products FRP Grating Machines play a role in grinding raw materials to create finely textured powders needed for uses such, as coatings or adhesives. The accuracy provided by these machines guarantees a distribution of particle sizes.

Role in Catalyst Preparation

In reactions, catalysts often need to have precise shapes and sizes to work most effectively. To meet requirements FRP Grating Machines are used to process these materials improving their performance, in reactions.

Contribution to Waste Management and Recycling

Machines with surfaces help in managing waste by breaking down leftover chemicals or faulty items into forms that can be used again reducing harm to the environment and encouraging sustainable methods, in various industries.

Factors to Consider When Choosing a FRP Grating Machine for the Chemical Industry

Material Compatibility and Machine Durability

When choosing a grinder machine it is important to make sure that it works well with the materials you are using it for processing.For example glass reinforced pipes need machinery that can handle rough materials without losing its strength and durability.

Capacity and Scalability for Industrial Needs

In settings large machinery that can adjust to different production needs is essential, for efficient operations.

Maintenance Requirements and Operational Costs

Maintenance is key in deciding the expenses over time especially in the long run when it comes to operations costs. Choosing machines that require maintenance can help maintain productivity without interruptions and cut down on costs, in the long term.

By incorporating state of the art technologies into their designs companies like Nine Excellence Corporation have created grating solutions customized for sectors, like FRM pipe production, storage tank fabrication and beyond.This dedication to progress guarantees that enterprises attain top notch outcomes while preserving affordability.

Technological Advancements in FRP Grating Machines

Integration of Automation and Smart Technologies

The use of automation and smart technology has completely transformed how FRP Grating Machines work nowadays. The latest FRP Grating Machines come with high-tech sensors and AI-powered systems that enable real-time monitoring and adjustments while in use. These advancements boost accuracy and efficiency by minimizing input. Automated systems maintain uniform material processing by identifying irregularities and adjusting to material characteristics. Furthermore, sophisticated technologies allow for maintenance reducing downtime and prolonging the equipment lifespan.

Development of Energy-Efficient Models

Energy efficiency is a priority in the evolution of modern FRP Grating Machines as manufacturers are incorporating energy-saving motors and refining machine designs to cut down power usage effectively. This progress notonly brings down operational expenses but also supports worldwide sustainability objectives. Energy-efficient models are especially advantageous in sectors like FRP (Fiberglass Reinforced Plastic) production where significant energy consumption is required for large-scale operations. These machines play a role, in promoting production methods by curtailing energy wastage.

FAQ

Where to buy a commercial-grade FRP Grating Machine?

You can buy professional grade FRP Grating Machines from manufacturers or suppliers that focus on meeting industrial requirements. Brands like ABC Company provide a variety of top notch FRP Grating Machines crafted for uses such, as chemical processing and creating FRP products. Their machinery is renowned for its robustness and efficiency while meeting the industry norms.

How to maintain a stainless steel FRP Grating Machine?

Ensuring the stainless steel FRP Grating Machines are long and function well requires proper maintenance practices, such, as regular cleaning to prevent material buildup on the blades and other parts lubricating moving components to reduce wear and tea,r and periodic inspection for any signs of damage or malfunctioning parts to maintain operational smoothness efficiently following the manufacturer’s maintenance guidelines can significantly prolong the lifespan of the machine.

What materials can a FRP Grating Machine process?

FRP Grating Machines are instruments that can work with different materials based on how they are designed and used. They typically deal with metals, plastics, wood, and composite materials like fiber glass-reinforced plastics (FRPs). In the chemical sector, these machines manage catalysts, powders, resins, and other key raw materials required for manufacturing processes such as those, foFRPPs pipes or storage tanks.

How does an electric FRP Grating Machine work?

Electric FRP Grating Machines work by utilizing a motor to power cutting or shredding blades that process the material fed into the machine through a feeding mechanism interacting with rotating or stationary blades to shred or grate the material into smaller pieces according to set standards. These advanced electric models feature automated controls to improve accuracy and efficiency while in operation.

Contact Us

For information on our selection of grate machines or help in selecting the appropriate model, for your industrial requirements feel free to contact Aoliande Company via our official website or customer service channels. Our team is committed to delivering customized solutions that cater to your needs while guaranteeing superior quality and performance.